Why Direct to Film Printing?

A New Frontier

Choosing Direct to Film (DTF) printing offers several advantages, especially in the textile and garment printing industry. Here's a summary of why one might opt for DTF printing:

- Versatility in Fabric Choice: DTF printing is compatible with a wide range of fabrics, including cotton, polyester, silk, and blends. This flexibility allows for diverse applications, from fashion to sportswear.

- High-Quality Prints: DTF printing produces vibrant, high-resolution images with excellent color saturation and sharpness. The prints are also known for their durability, resisting fading and cracking even after multiple washes.

- No Pretreatment Required: Unlike some other printing methods (like Direct to Garment), DTF does not require pretreatment of fabrics. This saves time and simplifies the printing process.

- Efficiency and Speed: DTF printing is suitable for both small and large-scale production. The process is streamlined, allowing for rapid production without compromising on print quality.

- Cost-Effectiveness: With DTF, the overall cost can be lower compared to other methods, especially for small to medium-sized runs. The setup costs are generally lower, and the process requires less labor.

- Ease of Use: The technology is relatively easy to use, with straightforward processes and equipment. This makes DTF printing accessible even for those with limited experience in textile printing.

- Eco-Friendly Options: The market for DTF printing includes eco-friendly ink options, catering to the growing demand for sustainable printing solutions.

- Reduced Waste: DTF printing minimizes waste compared to traditional methods, as it only uses the exact amount of ink and adhesive needed for each print.

- Flexibility in Design Changes: It's easy to make design changes between prints, offering flexibility for custom orders or limited edition runs.

- Soft Hand Feel: The prints produced have a soft hand feel, which is particularly desirable in the apparel industry.

Direct to Film (DTF) printing is favored for its ability to produce high-quality, durable prints on a wide variety of fabrics without requiring fabric pre-treatment, making it versatile and cost-effective. Its ease of use, coupled with the potential for rapid production and reduced waste, makes it an attractive option for both small-scale and large-scale textile printing applications.

An industrial DTF printer set-up consists of 7 key components:

- DTF PET Film

- Software of DTF Printer

- Hot-Melt Adhesive Powder

- DTF Printer Inks

- Automatic Powder Shaker

- Curing Oven

- Heat Press Machine

DTF PET Film

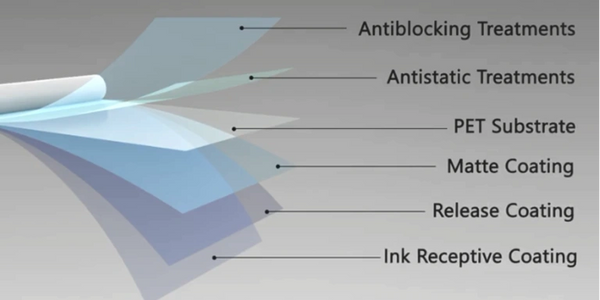

Direct to Film (DTF) PET (Polyethylene Terephthalate) film is an essential component in the DTF printing process, which is used in the textile industry for creating high-quality prints on various types of fabrics. Here's a summary of its characteristics and role in DTF printing:

- Material: DTF PET film is made from Polyethylene Terephthalate, a type of plastic commonly used in various applications due to its strength, stability, and transparency. The film serves as the base on which designs are printed.

- DTF Printing Process: In DTF printing, designs are first printed onto the PET film. Unlike traditional printing methods that print directly on fabric, DTF printing uses this film as an intermediary step.

- Ink and Powder Application: After printing the design with special DTF inks, an adhesive powder is applied to the film. The PET film's properties ensure that it can hold both the ink and the adhesive powder effectively until they are transferred to the fabric.

- Heat Transfer: Once the design is printed and the powder is applied, the film is then heat-pressed onto the fabric. The heat activates the adhesive, allowing the design to transfer from the film to the fabric.

- Versatility: One of the major benefits of DTF PET film is its versatility. It can be used to print on a wide range of fabrics, including those that are difficult to print on using other methods, such as cotton, polyester, silk, and blended fabrics.

- Quality of Print: The use of PET film in DTF printing allows for high-quality, detailed, and vibrant prints. The colors are typically bright and long-lasting, and the print has good wash durability.

- Eco-Friendly Options: Some DTF PET films are designed to be eco-friendly, catering to the growing demand for sustainable printing solutions in the textile industry

Transparent DTF PET films are the basis of the DTF technology. DTF PET films are available in multiple sizes, colors and different coating. Meaning, you must choose the appropriate one for your DTF inks and powders.

Two main specification of DTF films are single/double coated and hot/cold peel suitable. Each appropriate for different applications. Based on different coatings used for DTF films, quality differs highly.

DTF Printer Software

Direct to Film (DTF) printer software plays a crucial role in the DTF printing process, which is used for transferring designs onto various fabrics. Here's a summary of its key aspects and functionalities:

- Design Preparation and Management: DTF printer software allows users to prepare, edit, and manage their designs before printing. This includes tools for layout adjustment, color management, resizing, and other graphic editing functionalities.

- Color Profiling and Matching: The software typically includes advanced color management systems. These systems ensure accurate color reproduction and consistency between the digital design and the printed output on the film.

- RIP Software Integration: Many DTF printer software solutions integrate Raster Image Processor (RIP) software. RIP software is essential for converting images into a format that the printer can interpret, optimizing color accuracy and print quality.

- Printer Settings Control: The software provides control over various printer settings such as print resolution, ink drop size, and printing speed. These settings are crucial for ensuring the quality of the print and the efficiency of the ink usage.

- Efficiency and Workflow Optimization: DTF printer software often includes features that streamline the printing process, such as batch processing, which allows for the printing of multiple designs in a single operation. It also may include scheduling and queue management tools.

- Compatibility with Different Printers and Fabrics: Good DTF printer software is compatible with a wide range of DTF printers and can adapt to different types of fabrics and printing requirements.

- User-Friendly Interface: These software solutions are designed to be user-friendly, allowing both professionals and beginners to navigate and use the software effectively.

- Support and Updates: Regular updates and support are typical features, ensuring the software stays up-to-date with the latest printing technologies and industry standards.

In summary, Direct to Film printer software is a vital component of the DTF printing process, offering tools for design preparation, color management, and printer control. It enhances the efficiency, quality, and versatility of the DTF printing process, making it easier to achieve professional-grade fabric prints

Hot Melt Adhesive Powder

Direct to Film (DTF) hot melt adhesive powder is a crucial component in the DTF printing process, used for transferring printed designs onto fabrics. Here's a summary of its characteristics and role:

- Function: The adhesive powder is applied to the printed film after the design is printed. When heated, this powder melts and acts as an adhesive to bond the ink to the fabric.

- Types of Powder: There are different types of DTF adhesive powders available, varying in particle size, melting point, and color. The choice of powder depends on the specific requirements of the print job, such as the type of fabric and desired durability.

- Application Process: After printing the design onto the film, the powder is evenly distributed over the ink. Excess powder is then removed, leaving only the powder that sticks to the wet ink.

- Curing Process: The film with the adhesive powder is passed through a curing oven or heat press, where the powder is melted and bonded to the ink.

- Heat Transfer Step: During the heat transfer step, the film is placed onto the fabric and pressed with a heat press. The heat activates the adhesive, allowing the design to transfer from the film to the fabric.

- Compatibility with Fabrics: The adhesive powder is versatile and can be used to transfer designs onto a variety of fabrics, including cotton, polyester, and blends.

- Quality of Prints: DTF adhesive powder is crucial for ensuring high-quality prints. It helps in achieving vibrant colors, sharp details, and durability in wash and wear.

- Environmental Considerations: Some DTF powders are formulated to be more environmentally friendly, aligning with the increasing demand for sustainable printing solutions.

In summary, DTF hot melt adhesive powder is an essential element in the DTF printing process, responsible for binding the printed design to the fabric. It ensures versatility, quality, and durability of the prints on various fabric types.

DTF Printer Inks

Direct to Film (DTF) printer inks are specialized inks used in the DTF printing process, crucial for transferring high-quality designs onto various fabrics. Here's a summary of their key features and role:

- Type of Ink: DTF printer inks are typically water-based pigment inks. They are formulated specifically for DTF printing to ensure high-quality, durable, and vibrant prints.

- Color Range: These inks come in a standard color range, including CMYK (Cyan, Magenta, Yellow, Black) and often white. The white ink is particularly important in DTF printing as it is used as a base layer for colored designs, especially when printing on darker fabrics.

- Print Quality: DTF inks are designed to provide high-resolution prints with sharp details and bright, saturated colors. They have good opacity and color fastness, which ensures long-lasting and fade-resistant prints.

- Compatibility with Films and Fabrics: These inks are formulated to work well with DTF films and a wide range of fabric types, including cotton, polyester, and blends. The inks adhere effectively to the film and transfer cleanly to the fabric.

- Durability: Prints created with DTF inks are known for their durability. They withstand washing and stretching well, making them suitable for various textile applications, from fashion to sportswear.

- Curing Process: After printing, the inks must be cured, typically using a heat press. This process sets the ink on the film and prepares it for the heat transfer process.

- Eco-Friendly Options: Some manufacturers offer eco-friendly DTF inks, aligning with the growing demand for sustainable and environmentally responsible printing solutions.

- Storage and Handling: Proper storage and handling are important to maintain the quality and longevity of DTF inks. They should be stored in a cool, dry place and shaken or stirred regularly to prevent settling.

In summary, DTF printer inks are a specialized type of water-based pigment ink crucial for the DTF printing process, providing high-quality, durable, and vibrant prints on a variety of fabrics. They are an essential component for achieving detailed and long-lasting textile prints.

DTF Automatic Powder Shaker

A "direct to film automatic powder shaker" is a piece of equipment used in the textile printing industry, particularly in the process of Direct to Film (DTF) printing. Here's a summary of its function and importance:

- Direct to Film Printing Process: DTF printing is a method where designs are printed onto a special film, which is then transferred to fabric. This process is popular for its ability to produce high-quality, vibrant prints on various types of fabrics.

- Role of the Powder Shaker: After the design is printed onto the film, a powder adhesive is applied. The automatic powder shaker evenly distributes this powder over the printed film. This step is crucial as the powder ensures that the ink adheres properly to the fabric during the transfer process.

- Automation: The "automatic" aspect of the powder shaker indicates that the equipment is designed to dispense and distribute the powder uniformly and efficiently, without the need for manual intervention. This automation enhances consistency in print quality and speeds up the production process.

- Integration in the Workflow: The automatic powder shaker is an integral part of the DTF workflow. After printing and powder application, the film goes through a curing process to set the ink and adhesive before being pressed onto the fabric.

- Benefits: The use of an automatic powder shaker in DTF printing leads to increased productivity, consistent quality, and reduced labor costs. It also minimizes waste and mess that can be associated with manual powder application.

DTF Curing Oven

A Direct to Film (DTF) curing oven is an important piece of equipment in the DTF printing process, used for curing or drying the printed film before it is transferred to fabric. Here's a summary of its function and significance:

- Purpose: The primary function of a DTF curing oven is to cure the ink and adhesive powder that has been applied to the printed film. This process involves drying and solidifying the ink and adhesive to ensure they adhere properly to the fabric during the transfer process.

- Heat Application: The curing oven applies heat to the printed film. This heat is critical for activating the adhesive powder and ensuring that the ink sets correctly on the film.

- Consistent Temperature Control: These ovens are designed to provide consistent and even temperature distribution. This consistency is vital for ensuring that the entire surface of the film is cured uniformly, preventing issues like color distortion or inadequate adhesion.

- Speed and Efficiency: The use of a curing oven speeds up the drying process significantly compared to air drying. This efficiency is crucial in a commercial or industrial setting where time and throughput are key factors.

- Variety of Sizes and Types: DTF curing ovens come in various sizes and configurations, accommodating different production scales and workspace limitations. Some are designed for small-scale operations, while others are suited for large-scale industrial use.

- Quality Enhancement: Proper curing enhances the quality of the final print. It ensures that the print is durable, wash-resistant, and has vibrant colors that adhere well to the fabric.

- Integration in DTF Workflow: The curing oven is an integral part of the DTF workflow, positioned after the printing and powder application stages and before the heat transfer to the fabric.

In summary, a Direct to Film curing oven is essential in the DTF printing process for curing printed films, ensuring high-quality, durable, and consistent results in fabric printing. It enhances efficiency and quality control in the production workflow.

DTF Heat Press Machine

The heat press step in Direct to Film (DTF) printing is a crucial phase where the printed design on the DTF film is transferred onto the fabric. Here's a summary of this step:

- Preparation: After the design is printed on the DTF film and the adhesive powder is applied and cured, the next step is the heat press. The fabric onto which the design will be transferred is placed on the heat press machine.

- Positioning the Film: The DTF film with the printed design is then positioned on top of the fabric, with the printed side facing down.

- Heat and Pressure Application: The heat press machine applies heat and pressure to the film and fabric. The temperature and pressure are carefully controlled and can vary depending on the type of fabric and ink used. Typically, temperatures range from 150°C to 160°C (300°F to 320°F), and the press is applied for a specific duration, often around 15 to 20 seconds.

- Activation of Adhesive: The heat activates the adhesive powder on the film, causing the ink and adhesive to bond with the fibers of the fabric.

- Peeling off the Film: After the heat press, the film is removed. This can be done either while it is hot (hot peel) or after it has cooled down (cold peel), depending on the type of film and ink used.

- Final Result: The result is a high-quality print transferred onto the fabric. The print is typically very durable, flexible, and resistant to washing.

- Key Considerations: Consistency in heat and pressure is crucial for a successful transfer. Inconsistent heat or pressure can lead to poor quality transfers, such as incomplete transfer of the design, dull colors, or poor adhesion.

In summary, the heat press step in DTF printing is where the actual transfer of the design from film to fabric takes place. It requires precise control of heat and pressure to ensure high-quality, durable prints on the fabric.

Deze website maakt gebruik van cookies.

We gebruiken cookies om websiteverkeer te analyseren en de ervaring op je website te optimaliseren. Als je het gebruik van cookies accepteert, worden je gegevens gecombineerd met de gegevens van alle andere gebruikers.